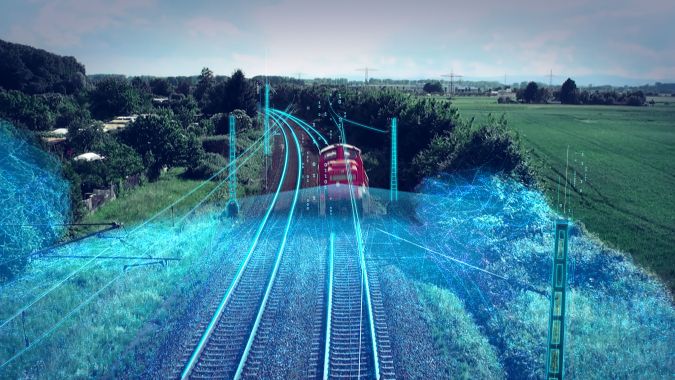

On track with a digital mindset

Siemens Mobility’s AI-enabled digital twin signals new approach to rail modernization

To maintain reliability and safety for passengers and freight, many of Europe’s rail networks are undergoing a massive digital modernization programme that includes digital twins. Backed by artificial intelligence (AI), these digital representations of rail systems are helping to facilitate the effective management of signals and inventory across the entire asset lifecycle. Siemens Mobility is playing a leading role in this development.

Siemens Mobility’s building information modelling (BIM) for rail infrastructure efforts encompass the full digitalization of the planning, construction and operation of rail assets, including signalling and structures along all of the lines. The company’s skilled technicians are putting digital twin techniques to work for Deutsche Bahn’s €12.7 billion (US$15.3 billion) programme to modernize its rail network.

Rebooting the infrastructure inventory

Integral to the German national railway company’s modernization efforts is the move to the European Train Control System (ETCS), the advanced signalling and control component of the European Rail Traffic Management System (ERTMS). The first component of the BIM modernization process is to document and digitize the signalling infrastructure of the Deutsche Bahn rail network. “Deutsche Bahn recognized early on that they needed valid data of the tracks before they could deploy ETCS,” says Carolin Baier, head of digital twin and digitalization for the domestic market of Germany at Siemens Mobility GmbH, supporting Deutsche Bahn to facilitate infrastructure capture of the inventory. “Our job is to reset or reboot the infrastructure inventory in different projects. That means we really need a clearer picture.”

Outdated as-built inventory information does not allow for accurate planning. Especially in large infrastructure projects, obtaining up-to-date data and information using traditional surveying methods is tedious and can cause major delays. In the past, this task would have required a survey team to measure using track wheels, along with mostly outdated paper plans.

Accuracy matters

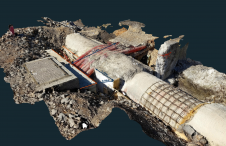

For Siemens Mobility, the process of data collection is built around a mobile mapping system that can be installed on trains, trolleys and cars, as needed. “It’s quite important that we are as accurate as two centimetres, in some cases. That specification guides the choice of collection method, in this case our high-precision surveying system,” adds Baier. The company relies on the vehicle-mounted Trimble MX9 mobile mapping system with dual-head laser and the AP60 IMU, the highest-grade IMU on the market. Trimble’s MX9 is the first vehicle-independent mobile mapping system officially approved by Deutsche Bahn for surveying tracks, points, clearances and topographic objects. The scanner is mounted on the train for streamlined data gathering.

Maximized results, minimal disruption

“The great thing about this mobile mapping solution is that we can gather information at normal train operation speeds, usually between 80 and 110km/h, and avoid business interruptions,” Baier continues. Siemens Mobility piloted the mobile mapping system in the Deutsche Bahn Netz AG Region East as part of an as-built data upgrade project. The resulting georeferenced 3D point cloud of the rail infrastructure included detailed images of the track, the track environment and the track gradient.

Data from multiple sources

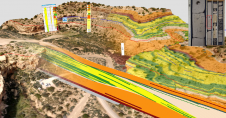

Besides the point cloud data and images from the MX9, the Siemens Mobility team incorporates a considerable amount of customer data into the digital 3D model from various other sources, such as geographical information systems (GIS) and the real estate register (ALKIS). All of this data is synchronized to create an as-built BIM model that is positioned within a global georeferenced coordinate system – in essence, a digital twin of the existing rail network and associated infrastructure (e.g. signals). The team then performs a gap analysis to check that the objects in the customer database match the positions in the point cloud.

The next step is to identify and extract system objects and to implement a complete system layout in the form of a scaled track layout. For instance, on a 500-800km segment, there might be around 120,000 different objects. “Rich data is great; it’s very detailed and, thanks to mobile mapping, we can capture it quickly. But AI is really the key to unlocking the power of data because it allows us to work with these large datasets in an efficient way,” Baier states.

Algorithmic advantage

Baier and her team worked with the Siemens Mobility AI group to develop customized algorithms for specific use cases, such as automatic object recognition of track elements. “Object detection and AI algorithms support current and future developments, allowing rail infrastructure optimization as well as train movement in semi-autonomous or fully autonomous systems. Without AI technologies to help sort out data, we could not develop these future systems,” she adds.

Baier believes the successful implementation of BIM in rail infrastructure, and the value of a digital twin, is the alignment of people, processes and technology. “The transition to ETCS and the future of rail operations will require a digital mindset. We are convinced that the application of BIM will soon contribute to making the process landscape in rail infrastructure even more efficient, which will in turn enable considerably more transparent collaboration,” she concludes.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)